This blog is intended as a very occasional series of rambling notes documenting my thoughts and original research relating to the 1845 Franklin Expedition.

Saturday, 19 February 2011

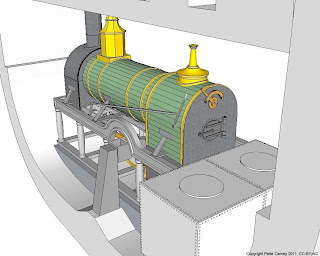

The Engine Room

These two images are my speculative reconstruction of the engine rooms of Erebus and Terror. The structure of the ship is based on the plans in the National Maritime Museum and the engine is based on SC Brees's drawings of what I believe to be the type of locomotive used. The engine is cradled by a substantial cast-iron framework supported by pillars. The two water tanks provide a platform for the engine's operators as well as serving their usual purpose Based on contemporary practices, the forwards thrust of the propeller is transmitted through the propeller shaft and the engine's driving axle to a thrust bearing supported by a cast-iron pillar bolted to ship's keel. Many details have been left out, for example, the pipe to allow waste steam to be vented to the open air, and the substantial timbers to make up the spare rudder which also shared the compartment. I hope it will not be too many years before the accuracy of my guesses can be tested against real evidence from one of the ships.

Subscribe to:

Post Comments (Atom)

Four Rusty Tin Cans in Three Different Sizes

In January 2024 I had the pleasure of visiting the beautiful and historic city of Bath to attend a fantastic presentation by Logan Zachary...

-

In January 2024 I had the pleasure of visiting the beautiful and historic city of Bath to attend a fantastic presentation by Logan Zachary...

-

I was amazed to discover recently that it is now ten years ago, in November 2012, that I had the privilege to travel to Nelson Mandela Rd,...

-

Images from the wonderful AMC's The Terror I shamelessly appropriate the language of Émile Zola's celebrated exposé of th...

These are extremely interesting - well done!

ReplyDeleteJust a small point, but why not try it with the waste steam pipe in situ? Also, since there seems to be no limit to your ability to produce compelling three-view images, what about one showing the external appearance of the ship(s) when they were steaming - how did the funnels conflict with the masts, sails and standing rigging, etc.?

I'm never satisfied...

I have really enjoyed reading these wonderful posts about the engineering of Franklin's ships. It has joined two boyhood interests. If you would please forgive my ignorance, I don't know anything much at all about either (locomotive engineering or Sir John), so how was the thrust transferred from the locomotive to the drive shaft for the propeller? A series of interlocking gears or a piston of some kind within the pillar? Was the axel left in place from the locomotive and it turned to function as a PTO to the propeller shaft via the pillar or were the pistons of the locomotive connected to the shaft instead via some sort of transfer/driving rods contained within the pillar? I have no idea what I'm talking about of course, but find this fascinating; and I didn't understand what was meant by "the engine's thrust was transmitted via a cast iron pillar". Many thanks for the splendid blog posts and any further elucidation.

ReplyDeleteHi William, it's a good point, the answer is that as I hadn't made up my mind how the steam pipe should go so I thought I'd better post these as they are otherwise I might never get round to it. I'd like to do some of the other views in the future but as always I've got so many jobs to do I don't know which way to turn. You might like a view of this video to see what a real expert can do http://www.youtube.com/watch?v=IIsra0OBDLA

ReplyDeleteMr Cook, Many thanks for your kind comments and raising a very good point. The fascination that this subject holds for me is that it joins any number of fields which would be interesting in their own right. I have revised the wording as it a little confusing originally.

ReplyDeletethe driving axle of the engine is directly coupled to the propeller shaft on the same line. This is in contrast to earlier screw-ships which used gears or chains to drive a fast turning propeller from a large but slow turning engine.

When the propeller is rotated it pushes forward on its shaft and that pushing force is the thrust which drives the ship forward.

The cast-iron pillar, and the thrust-bearing it supports, is the part of the ship's structure which the thrust from the propeller presses against. Only later were bearings developed which enabled the thrust to be transmitted directly from the propeller shaft to the ship's structure without it passing through the engine's axle as it does in this case. I hope that helps to clear up, rather than contribute to, the confusion.

Thanks so much, that helps greatly!

ReplyDeleteThis comment has been removed by the author.

ReplyDeletePeter, excellent work! This is best-informed reconstruction I've seen yet.

ReplyDeleteAt the same time, to my mind it reinforces the reality of how limited they likely were in actual usefulness; taking the torque of such an engine and the design of the propellor into account, it seems to me that it would have taken quite a lot of effort -- and a lot of coal -- to get one of these things up to steam.

Interestingly, in one of his last letters, Franklin himself commented on the circumstances in which he planned to use these engines: "The Ships have now been fitted with a locomotive Engine & screw to propel them in Calms & when the Lanes[?] of water trend directly in the winds' Eye."

Thanks Russell. With hindsight, it does appear that the very limited capability of the engines was far out of step with the optimism expressed beforehand. Captain Crozier seems to have been the only one not to be enthralled by the power of steam and in this case I'd say that history had proven him right

ReplyDeleteThanks for great sharing. When the required gear is selected, the dog clutch locks that gear onto the output or propeller shaft. stern drive propeller The below propeller brands will fit on your selected MerCruiser engine. However, to ensure proper loading of your engine, please choose the propeller size that most correctly matches your existing propeller. Please use the engine filter above to narrow your MerCruiser propeller options to your specific engine.

ReplyDeletegood one

ReplyDelete